Main

When designing a manual of operating assembly lines the following factors should be considered:

- Ergonomic design

The following presentation focus on balancing and optimizing the cycle times and the results that should be achieved.

But let's see what the exact definition is:

- Material flow planning processes

- Preparation of work instructions

- Cycle time adjustment and optimization

- Set Design Optimization

- Preparation of work instructions

- Cycle time adjustment and optimization

- Set Design Optimization

The following presentation focus on balancing and optimizing the cycle times and the results that should be achieved.

But let's see what the exact definition is:

By Cycletime we understand the time between two products passing through the system.

The theoretical and practical cycletime of manufacturing systems is the relationship of capacity to time norm, by which the following results can be achieved:

- Increase of manufactured pieces

- Reduction of unproductive time

- Improved quality

- First step towards one-piece flow

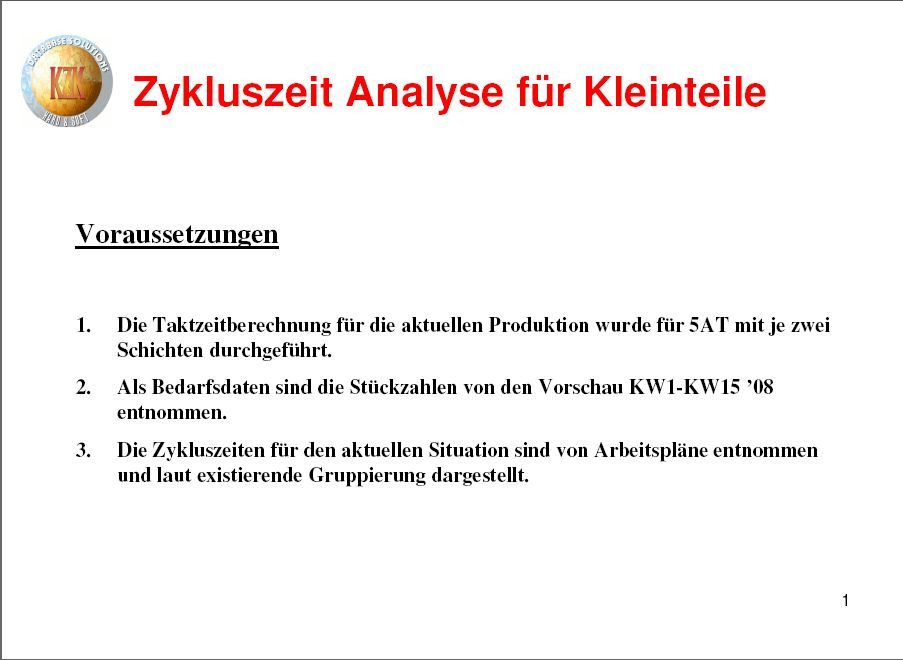

The presentation is in German made by an Austrian company:

Click the picture above to download the training material in PDF format.

More about it You can read in my Newsletter